Flux Meaning In Soldering . Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. Types of flux for soldering electronics. The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. To prepare metal surfaces for soldering. As with most things related to soldering, that begins with wetting forces. Solder flow is called wetting. Understanding flux requires comprehension of what it does. Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. Flux, in the context of soldering, is a chemical agent that has one primary goal: As an owner of solderingironguide, i went. It isn’t enough to just use any flux agent to solder wires and electronics. Flux is indispensable in achieving the perfect bond during the soldering process.

from www.walmart.com

Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. It isn’t enough to just use any flux agent to solder wires and electronics. To prepare metal surfaces for soldering. The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. As with most things related to soldering, that begins with wetting forces. Flux, in the context of soldering, is a chemical agent that has one primary goal: Solder flow is called wetting. Understanding flux requires comprehension of what it does. Flux is indispensable in achieving the perfect bond during the soldering process. Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or.

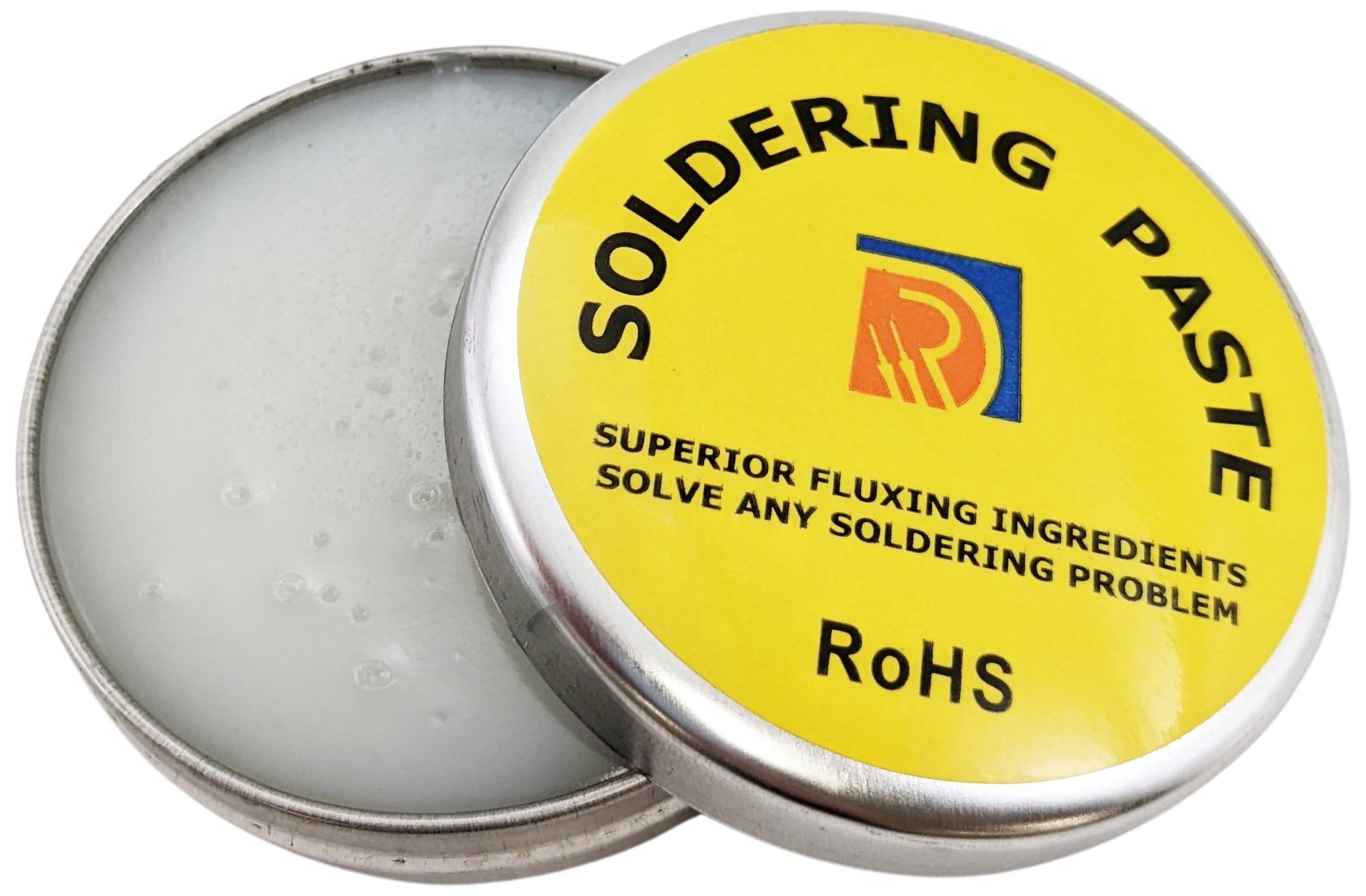

Soldering Flux Paste, 50 Gram Jar, RoHS Compliant, Helps Solder Flow

Flux Meaning In Soldering Solder flow is called wetting. Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. As with most things related to soldering, that begins with wetting forces. Flux is indispensable in achieving the perfect bond during the soldering process. As an owner of solderingironguide, i went. The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. It isn’t enough to just use any flux agent to solder wires and electronics. To prepare metal surfaces for soldering. Flux, in the context of soldering, is a chemical agent that has one primary goal: Understanding flux requires comprehension of what it does. Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. Types of flux for soldering electronics. Solder flow is called wetting.

From www.wikihow.com

Simple Ways to Use Soldering Flux (with Pictures) wikiHow Flux Meaning In Soldering Solder flow is called wetting. Types of flux for soldering electronics. Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. Flux is indispensable in achieving the perfect bond during the soldering process. To prepare metal surfaces for soldering. The soldering flux is a chemical substance that helps and facilitates the. Flux Meaning In Soldering.

From soldersandfluxes.co.uk

Solders & Fluxes About Us Soldering product in convenient sizes Flux Meaning In Soldering Understanding flux requires comprehension of what it does. As an owner of solderingironguide, i went. Types of flux for soldering electronics. To prepare metal surfaces for soldering. It isn’t enough to just use any flux agent to solder wires and electronics. The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect. Flux Meaning In Soldering.

From electronicshacks.com

Can You Solder Without Flux? ElectronicsHacks Flux Meaning In Soldering To prepare metal surfaces for soldering. Types of flux for soldering electronics. Understanding flux requires comprehension of what it does. It isn’t enough to just use any flux agent to solder wires and electronics. Flux is indispensable in achieving the perfect bond during the soldering process. As with most things related to soldering, that begins with wetting forces. Solder flux. Flux Meaning In Soldering.

From www.engineeringinhindi.com

Why Use Flux in Welding Enhancing the Welding Process Flux Meaning In Soldering To prepare metal surfaces for soldering. Understanding flux requires comprehension of what it does. Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. Types of flux for soldering electronics. Solder flow is called wetting. Flux, in the context of soldering, is a chemical agent that has one primary goal: As. Flux Meaning In Soldering.

From solderingironguide.com

How to Use Flux When Soldering Electronics For Beginners Flux Meaning In Soldering It isn’t enough to just use any flux agent to solder wires and electronics. Types of flux for soldering electronics. Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. Solder flow is. Flux Meaning In Soldering.

From www.youtube.com

What is Solder Flux? Soldering Basics YouTube Flux Meaning In Soldering As with most things related to soldering, that begins with wetting forces. To prepare metal surfaces for soldering. Understanding flux requires comprehension of what it does. Solder flow is called wetting. Types of flux for soldering electronics. It isn’t enough to just use any flux agent to solder wires and electronics. Flux acts as an indispensable agent in cleaning and. Flux Meaning In Soldering.

From hackaday.com

What The Flux How Does Solder Work Anyway? Hackaday Flux Meaning In Soldering Solder flow is called wetting. Understanding flux requires comprehension of what it does. Flux is indispensable in achieving the perfect bond during the soldering process. As with most things related to soldering, that begins with wetting forces. As an owner of solderingironguide, i went. The soldering flux is a chemical substance that helps and facilitates the soldering process, while having. Flux Meaning In Soldering.

From solderingironguide.com

How to Use Flux When Soldering Electronics For Beginners Flux Meaning In Soldering Solder flow is called wetting. Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. Flux is indispensable in achieving the perfect bond during the soldering process. As with most things related to soldering, that begins with wetting forces. Flux, in the context of soldering, is a chemical agent that has one primary goal: Solder flux. Flux Meaning In Soldering.

From solderingironguide.com

How to Use Flux When Soldering Electronics For Beginners Flux Meaning In Soldering Solder flow is called wetting. Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. As with most things related to soldering, that begins with wetting forces. The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. Flux is indispensable in achieving the. Flux Meaning In Soldering.

From www.electronicsandyou.com

What is Solder Flux How to Use Flux in Soldering Flux Meaning In Soldering Flux, in the context of soldering, is a chemical agent that has one primary goal: Solder flow is called wetting. Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. Flux is indispensable in achieving the perfect bond during the soldering process. As with most things related to soldering, that begins with wetting forces. As an. Flux Meaning In Soldering.

From www.tilgear.info

Flux Soldering Tilgear Flux Meaning In Soldering Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. To prepare metal surfaces for soldering. Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. Flux, in the context of soldering, is a chemical agent that has one primary goal: Understanding flux requires comprehension of what. Flux Meaning In Soldering.

From agdop.weebly.com

Solder flux agdop Flux Meaning In Soldering Understanding flux requires comprehension of what it does. Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. As with most things related to soldering, that begins with. Flux Meaning In Soldering.

From www.protoexpress.com

A Practical Guide to Soldering Flux Sierra Circuits Flux Meaning In Soldering Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. Understanding flux requires comprehension of what it does. As with most things related to soldering, that begins with wetting forces. Flux, in the context of soldering, is a chemical agent that has one primary goal: Flux acts as an indispensable agent. Flux Meaning In Soldering.

From www.rlctalk.com

What Is The Difference Between Solder Flux And Solder Paste? Flux Meaning In Soldering Types of flux for soldering electronics. As with most things related to soldering, that begins with wetting forces. Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. As an owner of solderingironguide, i went. Understanding flux requires comprehension of what it does. The soldering flux is a chemical substance that. Flux Meaning In Soldering.

From www.protoexpress.com

A Practical Guide to Soldering Flux Sierra Circuits Flux Meaning In Soldering The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. Understanding flux requires comprehension of what it does. Flux is indispensable in achieving the perfect bond during the soldering process. Types of flux for soldering electronics. To prepare metal surfaces for soldering. Solder flux is a substance. Flux Meaning In Soldering.

From bltcircuitservices.co.uk

WAVE SOLDERING FLUXES BLT Circuit Services Flux Meaning In Soldering Understanding flux requires comprehension of what it does. Solder flow is called wetting. Flux, in the context of soldering, is a chemical agent that has one primary goal: The soldering flux is a chemical substance that helps and facilitates the soldering process, while having a protective effect and preventing oxidation reactions. Types of flux for soldering electronics. As with most. Flux Meaning In Soldering.

From www.amazon.in

Stainless Steel Soldering Flux 20mL Amazon.in Home Improvement Flux Meaning In Soldering Solder flux is a substance that helps clean and forms a strong bond between parts of the electronics or. Understanding flux requires comprehension of what it does. Flux is indispensable in achieving the perfect bond during the soldering process. Solder flow is called wetting. Flux acts as an indispensable agent in cleaning and preparing metal surfaces for soldering. Types of. Flux Meaning In Soldering.

From www.youtube.com

What Is Flux? Soldering YouTube Flux Meaning In Soldering As with most things related to soldering, that begins with wetting forces. As an owner of solderingironguide, i went. It isn’t enough to just use any flux agent to solder wires and electronics. Flux, in the context of soldering, is a chemical agent that has one primary goal: Types of flux for soldering electronics. Flux is indispensable in achieving the. Flux Meaning In Soldering.